Types of Flywheels- A Comparison

Recently, we discussed the history and basic workings of the Flywheel UPS system, but did you know that there are also several different types and configurations of these systems? This article goes into more detail regarding the three main styles of Flywheel UPS.

Flywheel UPS

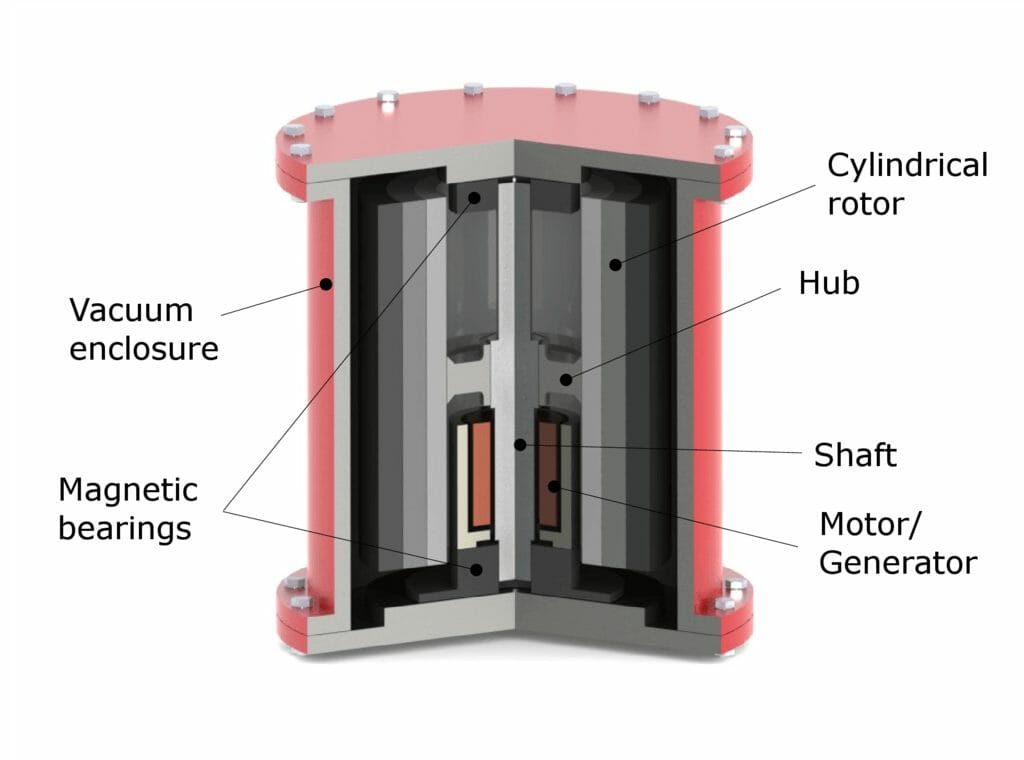

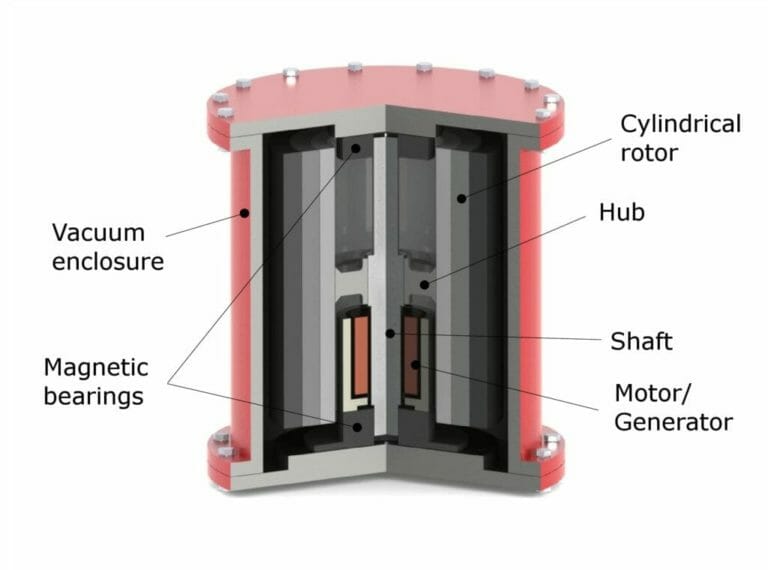

Conceptually, this system is simple. A rotor is suspended by magnetic bearings in a vacuum chamber, connected to an electric motor and an electric generator. The rotor accelerates to high speed in a drum and maintains its rotational energy until that energy is ready to be used. When the energy is released, the rotational speed of the flywheel is reduced. Adding energy increases the speed of the flywheel. Most FES systems use electricity to accelerate and decelerate the flywheel.

Flywheel UPS systems are typically better at operating in harsher environments, where they can help “smooth out” power disturbances. They are often seen in Manufacturing, Oil and Gas Industries, and even some science labs, where large energy charges need to be released in short bursts. These are all examples of a good use for a flywheel UPS.

Flywheel UPS Advantages:

- Long lifetimes. Flywheel UPS systems often are able to handle rough environments with longer mean time between failures.

- The magnetic bearings need little maintenance and typically they need replacement every 8 to 10 years.

- Rapid system charging in less than 15 minutes saves time and money.

- They typically have a smaller physical footprint than battery based UPS systems.

- They are not as adversely affected by temperature changes, and can operate in a much wider temperature range.

- They are less potentially damaging to the environment, being made of inert or benign materials.

Flywheel UPS Disadvantages:

- Unless they are couple with batteries, the run-time of a flywheel UPS is very short, typically measured in seconds. This can be risky in situations where a generator may have a starting delay.

- Flywheel design has limits, like the tensile strength of the material used for the rotor. If the tensile strength of composite flywheels outer cover is exceeded, the binding cover will fracture, followed by the flywheel shattering as outer wheel compression is lost around the entire circumference, and all stored energy is released at once in a “flywheel explosion.” Parts of the flywheel will fly off with the speed comparable to a bullet being shot from a gun (think shrapnel!)

- They can also have a bearing failure from vibration. Parts of the metal can bend outward and begin dragging the outer containment vessel, or separate completely and bounce randomly around the interior. Because of this, flywheel UPS require strong containment vessels as a safety precaution. Many companies put their system in the ground to halt any material from escaping the containment vessel.

Static UPS coupled with Flywheel

This is often the most popular type way a flywheel is used as a UPS. It is built on the same type of technology and footprint of a standard static UPS system, but in place of the batteries, a flywheel is used to provide run-time and power conditioning to the DC Buss of the UPS unit. This system is typically marketed as a way to eliminate the need for batteries and, as a result, decrease costs.

However, businesses that require a longer ride-through for power system outages, will look to either additional flywheel units, or will integrate batteries in addition to the flywheel to increase their run-time in the event of a generator failure or other issue.

Advantages:

- Static UPS are typically very stable. A flywheel is typically more robust and can be installed in harsher environments where a standard VRLA battery may not be sufficient.

- If they are coupled with batteries, run-time can be greatly extended.

- If coupled with batteries, it does not have a single point of failure. In the event that the flywheel fails, the batteries can continue to support the critical loads.

Disadvantages:

- Cost is a large disadvantage. Auxiliary costs are higher due to the flywheel addition. Maintenance costs can also be higher than a stand-alone flywheel if there are additional battery maintenance and replacement costs.

- Battery and flywheel UPS set-up only works well in conditioned environments that are suited for standard VRLA Batteries.

- Battery charging for this set-up is needed. Charge time is largely dependent on the number of batteries involved and their size.

Diesel Rotary UPS (DRUPS)

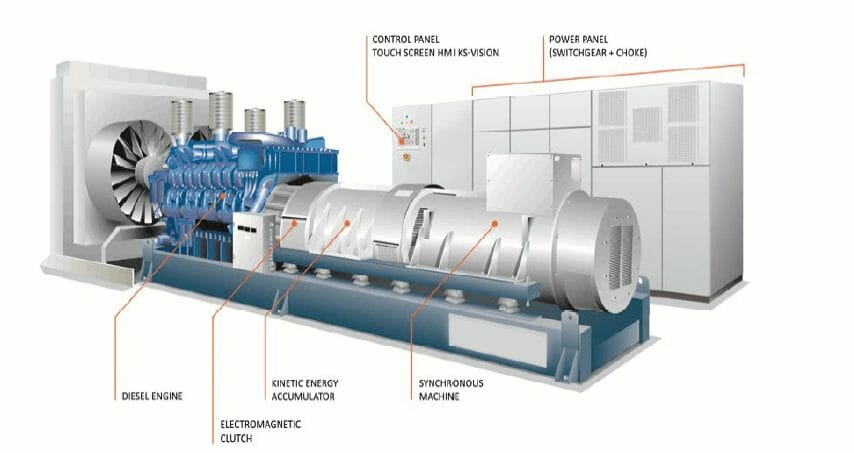

A DRUPS combines the functionality of a flywheel protected UPS with a diesel generator.

When combined with a reactor or a choke coil, the generator also works as an active filter for many power quality problems, such as harmonics, RFI, and frequency variations. When the utility or main power source fails, energy released in the flywheel drives the electric generator, which continues providing power without interruption. At the same time, the diesel engine takes over the flywheel to drive the electric generator to make required electricity. The flywheel continues to support the generator to keep a stable output frequency.

Because of the unique design of coupling the flywheel with the generator, there are other advantages too, including the ability of the flywheel inertia to start the generator in the event of a failed battery or other starting component failure, similar to how one would clutch start a manual vehicle.

The DRUPS are often seen in larger manufacturing and automation environments. They can be used for niche applications in military and industrial work. It is like a mini “power plant” for the company using it. In addition, they are becoming more popular in data centers and IT environments where space is a premium.

Advantages

- Typically, if you compare DRUPS to battery powered UPS with a generator, it has a higher overall system energy efficiency.

- It has a smaller comparable footprint to battery UPS and traditional generator

- The DRUPS also has a longer technical lifetime, as it has fewer electronic components that can be prone to failure.

Disadvantages

- DRUPS are mechanical devices and are typically maintained similar to a generator rather than a UPS system. Their cost to maintain, however is higher than that of a standard generator

- DRUPS can be a noise concern without sound attenuation. They are typically installed in external buildings due to noise from the generators, their size, and the fumes they emit.

Maintenance on a flywheel UPS environment is recommended at least twice a year. Quality Power Solutions has proven experts that can make designing and maintaining the right solution easier for you. Contact us today to find out more about how we can help!

Take a deep dive into how Flywheel Uninterruptible Power supplies work—read our series of articles about Flywheel UPS.

As data centers, manufacturing and other facilities look to increase power quality and reliability, they are faced with a choice of UPS systems. There are a…

Recently, we discussed the history and basic workings of the Flywheel UPS system, but did you know that there are also several different types and…

In the world of emergency power, your equipment is only as good as its ability to stay on when the lights go out. Most backup…

Is a Flywheel UPS right for your organization? Get in touch with the experts at QPS to find out more.

Published on Jul 10 2024

Last Updated on Apr 09 2025