UPS Battery Supply Chain Shortages

With Covid 19 dramatically slowing or halting many of our supply chains, have you considered how this will affect your UPS and the critical equipment that it protects? While service is still being performed, we have seen increased delays with one of the key consumables in your UPS—the battery. See how we can help you plan your next battery replacement project.

Shipping and Supply Chain Issues

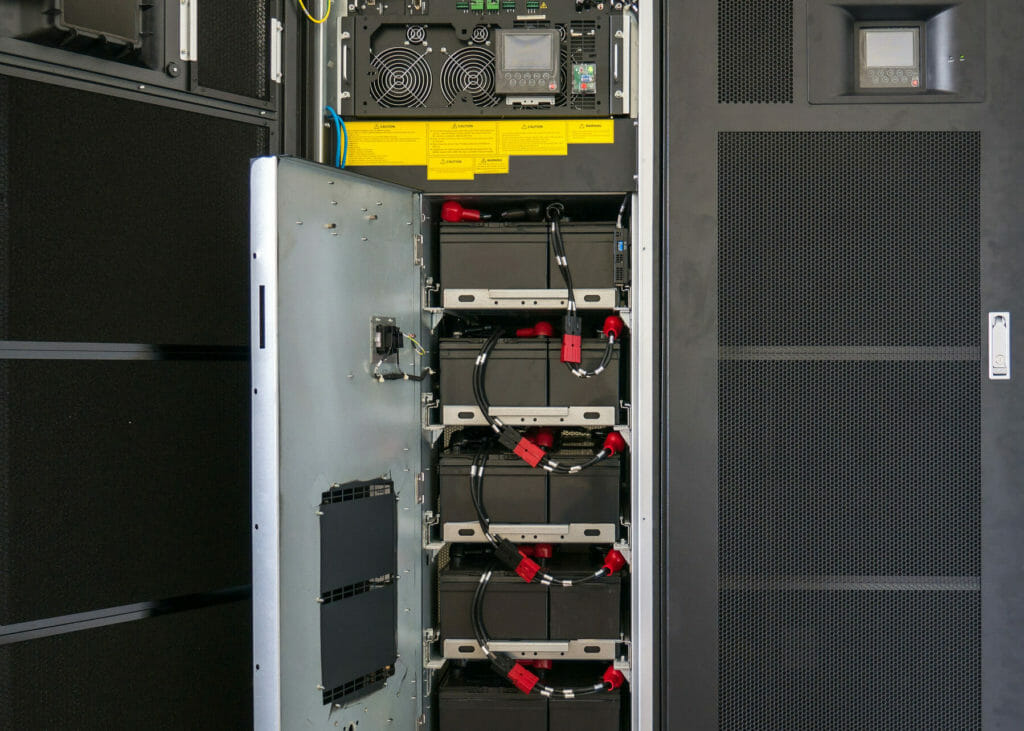

VRLA (Valve Regulated Lead Acid) Batteries have been the batteries of choice for many reasons including low maintenance, low price, and reliability. Just like every other product, however, we have been seeing supply chain-related delays. Smaller batteries that are commonly used in 1-5 kVA UPS units or which make up battery modules used in larger units have seen the longest delays as these often manufactured outside of the US. With the shipping congestion in US ports, thousands of batteries are stuck off-shore. If that wasn’t bad enough, COVID has forced many of these overseas plants to shutter their doors temporarily.

Large Batteries are also not immune to the supply chain issues that have been plaguing the smaller units. While often these batteries are manufactured domestically, dealing with shipping inconsistencies has been a very real problem both with obtaining raw materials for production and transporting the finished product to customers.

What to Expect?

Delayed Battery Shipments for UPS System Batteries

With the delays surrounding the shipping of finished and raw materials, expect extended delayed delivery dates of batteries. This can dramatically impact your facilities need for replacement batteries quickly in the event of a failed cell, or other pressing need.

Rising Battery Costs

The cost of batteries will likely continue to increase. While some manufacturers haven’t adjusted pricing over the last few months, it is reasonable to expect to see wholesale costs go up shortly. Labor shortages, pent up demand, and material shortages all point to increases in costs.

What Can You Do?

Plan ahead

At QPS, we work with our clients to plan ahead for large capital expenditures, battery replacements or other needs, often 18 months or more in advance of when the repair or expenditure might be needed. This is especially important when looking at a battery replacement, UPS capacitor replacement or other capital expenditure.

Source an alternate UPS battery

In some situations, it is possible to source an alternate brand or UPS battery model if your battery is not available. When considering an alternate, here are a few of the considerations we review:

- Charge / Discharge Charateristics

- Amp Hour (Ah) Rating or Watts per Cell (WPC)

- Physical Size

- Terminals

- Quality / Weight

QPS can help provide guidance around procurement of UPS battery alternates if needed, just let us know!

Reach Out to QPS For Battery Supply Planning & Fulfillment

The most important thing that you can do to help you navigate the current battery shortage is to reach out to QPS. Your dedicated account manager will help to determine when your batteries need to be replaced.

Our account managers are working diligently to make sure customers are aware of this shortage, and we are placing orders so you can receive necessary battery replacements as soon as they are available.

Our procurement team has been working nonstop to sourcing like for like batteries as well as alternate models.

While the next few months will become very difficult for battery replacements, our team at Quality Power Solutions is here to help you. Reach out to us below to see how we can be a resource for you.

Published on Feb 09 2022