Arc Flash Analysis: An Easy Guide

Arc Flash is an often-heard buzzword in the industry, but what does it mean and how does it affect your facility? In this easy guide, we’ll cover the basics that you’ll need to ensure that you are not only compliant, but also providing a safe environment for your employees, vendors and customers.

1) What is Arc Flash?

An electric arc is defined as a “luminous bridge” formed in a gap between two electrodes.” While this may sound harmless, in the right conditions, an arc event can be extremely dangerous and even deadly. An arc flash is caused by a fault or short circuit event that passes through this arc/air gap. This arc causes the air between the electrodes or conductors to ionize and can expel incredible amounts of deadly energy that is instantaneous and explosive. An arc flash event can reach instant temperatures as high as 35,000 degrees Fahrenheit – hotter than the surface of the sun.

An arc flash incident can liquefy or vaporize most materials including copper, aluminum and steel equipment parts. These materials can expand rapidly in volume as the turn from a solid state into a vapor and create a concussive force that can further spread damage and create a hazardous environment. Here’s what an Arc Flash looks like (viewer discretion advised):

2) What can cause Arc Flash?

An Arc Flash can be caused by various events including:

- Human error or accidental contact

- Foreign objects such as tools or items stored on top of components

- No preventative maintenance or equipment inspection

- Unnoticed buildup of debris, insects, dust or other items can also create a dangerous environment increasing the possibility of an arc flash event to trigger

3) How can an employer protect their facility?

Preventing a hazardous incident is crucial when dealing with arc flash. In fact, an article published in Fire Engineering Magazine (July, 2009), cites that there are an average of two fatal arc flash incidents per day. While these incidents might be various electrical mishaps, it certainly drives home the point that the energy potential that is present in many places of employment should not be overlooked.

OSHA 1910.132(d) states that employers must “assess the workplace for hazards”, provide for training for employees to safely work when near by energized equipment, and provide PPE for appropriate protection.

OSHA 1910.132(d) states that employers must “assess the workplace for hazards”, provide for training for employees to safely work when near by energized equipment, and provide PPE for appropriate protection.

The National Fire Protection Association (NFPA) 70E requires that an arc flash risk assessment be completed. Section 110.16 of the National Electric Code (NEC) also requires that electrical equipment be marked to warn qualified personnel of the potential arc flash hazard. It is important to understand how the code affects your facility and what are the specific responsibilities of the host employer and/or equipment owner.

Beyond the legal requirement and the potential for fines, the most important thing that an employer should consider is the safety of their employees.

Making sure that your employees go home to their families at the end of their shift should be paramount to an organization’s values.

To help a company understand their risk and ensure compliance, many organizations look to outsource Arc Flash Risk Assessment projects. Providers that offer Arc Flash risk assessment services can vary significantly in scope and deliverable.

4) What is an Arc Flash Risk Assessment?

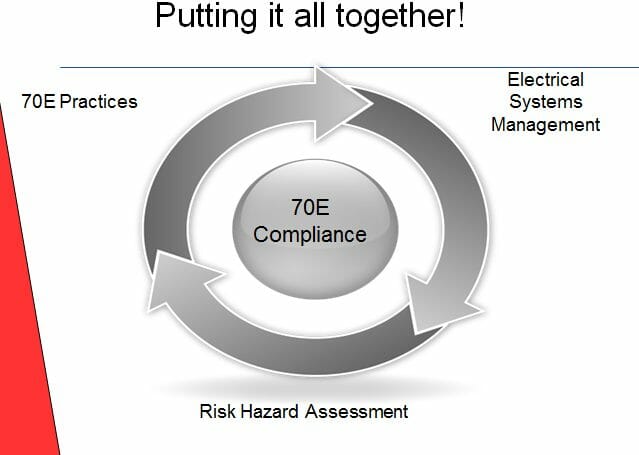

An arc flash study is not as simple as it might seem. An arc flash risk assessment is more than “posting” arc flash labels. Full compliance with all standards of NFPA 70E should be the overall mission, and the arc flash risk assessment project will be a baseline for meeting many of the standards.

An arc flash risk assessment project should include:

- A complete inventory of the electrical system

- A place to document future test and inspections of the electrical system

- An audit of “condition of maintenance” including Infrared testing, ultrasonic testing, visual inspection for NEC violations. This would include conditions within the equipment that may adversely impact the arc flash calculated results.

- Proper labeling on all electrical equipment

- One-line diagrams

- A short circuit audit of all installed electrical equipment.

- A coordination assessment to identify mis-coordinated device pairings which risk a greater portion of the electrical system to shutdown under certain fault conditions

- Arc Flash Electrical Safety training including awareness, proficiency and training for non-qualified individuals

- Support for the development of an ongoing program of 70E compliance and safety program sustainability.

It’s not just a label project or a final report binder to be stored on the shelf.

Managing an active electrical safety program is the mission, and the arc flash risk assessment is the setting of the “baseline.”

This arc flash risk assessment project scope is designed with the safety of your staff and your contractors as the highest priority.

Take the time to discuss a facility arc flash engineering study with a QPS representative today.

Published on Feb 03 2016